Location Management, transaction processing and inventory analysis and reporting are the three major functions of INVENTORY+PLUS (IVT+PLUS).

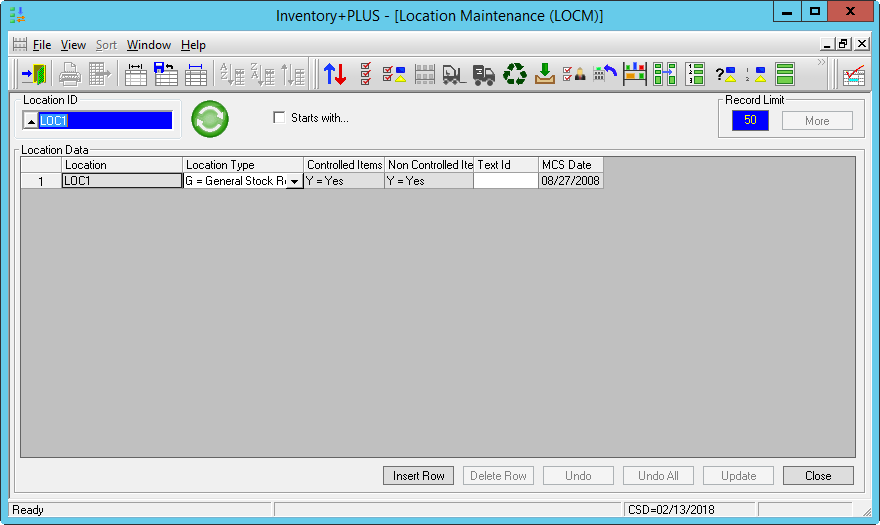

Location management consists of three functions. First, locations may be defined either in advance for the best control or as transactions are processed. If the locations are specified in advance then an indicator is set identifying whether only lot-traced items may be stored in the location, only non lot traced may be stored in the location or if both lot traced and non lot traced items may be stored in the location.

Second, flexible location control policies, specified by item, match the level of control to the nature of the item. The least control is provided by the random option. If this option is selected then an Item may be located anywhere. IVT+PLUS will keep track of where the Item is stored as a by-product of transaction processing. The existence of the indicated Location is not verified. If the location was not defined to IVT+PLUS then the location will be automatically added to the database. The next level of control is verified random. If this option is selected then an item stored only at established locations. However, the assignment of these locations need not be predefined to the item. The highest level of control is provided by the fixed option. If this option is selected then the location must be defined as well as the items that may be stored in that location.

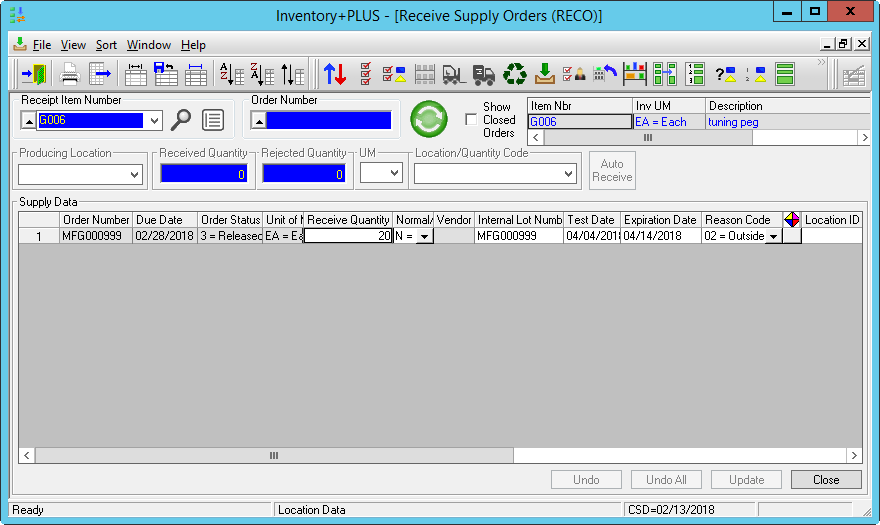

Third, transaction processing consists of receipts, issues, adjustments, moves, and transaction history analysis. When goods are received you can specify by item the status of the received goods. The Item, for example, may be placed in a quarantined status, which means it is available for planning but cannot be issued to production or it is made immediately available for issue. The receipt mixing code, specified by item, is useful for enforcing a FIFO (First In, First Out) inventory rotation policy. For each location/quantity code combination of an Item, IVT+PLUS automatically maintains a last receipt date to identify the age of materials. If the receipt mixing policy is set to No then IVT+PLUS would prevent material from being moved into or received into a location that already contains this item. Each receipt transaction contains a reason code and text such as inspection procedures may be linked to the transaction. Accounts Payable, if operative, is notified of the receipt.

To support various manufacturing environments IVT+PLUS provides three methods for reporting material issues. First, if manual issue is used then the user submits an issue transaction to relieve each component demand. Second, if automatic issue is used then the receipt transaction triggers the relief of component demand. Automatic Issue may not be used with lot-traced items. Third, if Group Issue is used then inventory is relieved when the Group Issue transaction is submitted.

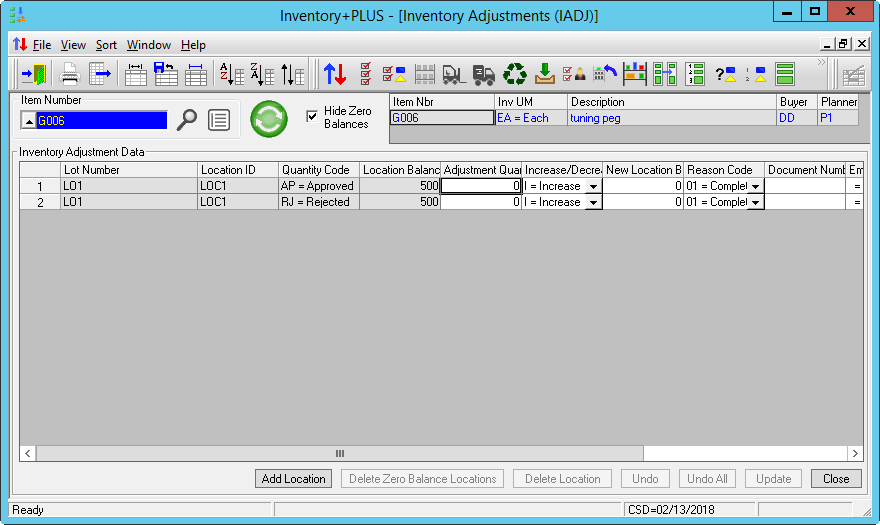

Adjustments are made to either correct errors or issue inventory for non-production use. Each adjustment transaction contains a reason code. This reason code can be used by the Cost Management Module (CMS+PLUS) to assign costs by reason code.

Moves are used to transfer inventory from one location to another. A typical use would be to transfer inventory from on-hand to quarantined upon the discovery of a quality problem.

All of these transactions are stored in an Inventory Transaction History table. Transaction type, user, date range, item number, and lot number among others may be used to analyze these transactions

ABC Analysis and Excess and Obsolete are the significant analytical reports produced by IVT+PLUS. ABC analysis classifies all items according to predetermined classes of period usage value. The classes are defined in terms of a percentage of the total usage value or as a function of quantity of individual item period usage. A typical classification is three-class ('A', 'B', and 'C'), where 'A' contains the highest usage value parts, and the total of Class A's parts accounts for 80 percent of the total period usage value. The period may be a past period, a future period, or a combination of both. Past period's usage is calculated user-specified look-back horizon. A future period's usage is calculated as the sum of the requirements over a user specified horizon. The Total Period Usage Quantity is the weighted average of Past and Future Usage Quantities. The weight factors are user-specified. The ABC Analysis Report displays the result of this analysis. This report is intended to assist management in constructing and maintaining a priority structure that determines the level and frequency of control procedures for every item.

The Excess and Obsolete Report is, perhaps, the most valuable of the IVT+PLUS reports. Usage is calculated based on the sum of historical and expected future usage. Historical usage is calculated user-specified look-back horizon. A future period's usage is calculated as the sum of the requirements over a user specified horizon. The report identifies those inventory items where the inventory balances exceed the calculated usage. The report, furthermore, identifies those items for which unnecessary orders exist. The identification of unnecessary orders, especially purchase orders, enables you to conserve cash by cancelling the orders. From a production perspective the cancellation of unnecessary orders frees up capacity. The assiduous use of this report helps you prevent the acquisition of material that is of no value.