The Customer Order Management Order Entry System (OMS+PLUS/OE) is the repository of all customer orders. Customer orders are the organization's internal representation of a customer's purchase order. The prerequisites for this module consist of Itemizer+PLUS, IVT+PLUS, OMS+PLUS/PD and OMS+PLUS/AD. The major features of OMS+PLUS/OE consist of three-tiered architecture, expansive address support, convenient customer order maintenance options, order status options, multiple order hold codes, and instant Available to Promise and Stock Status queries.

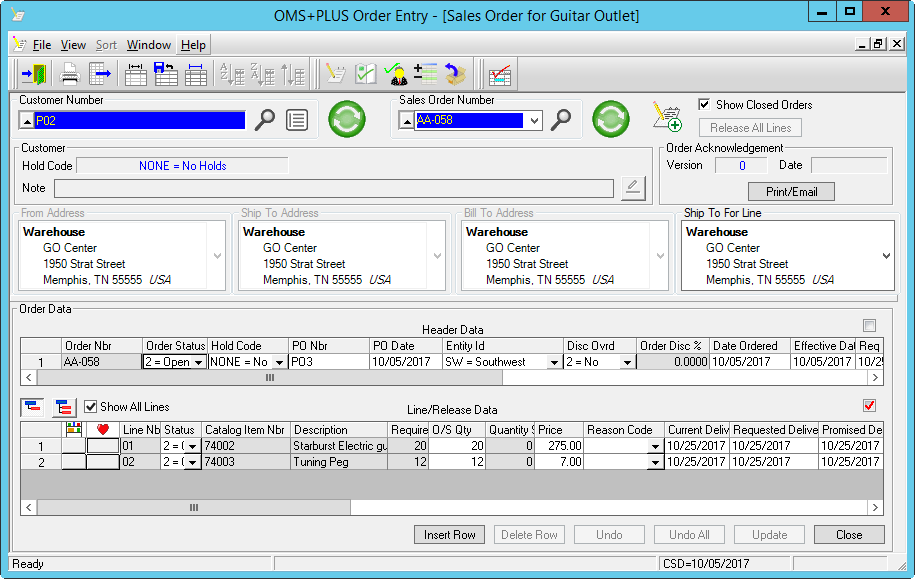

The three-tiered structure of a customer order provides the utmost flexibility. The first tier is the customer header. This table contains all of the administrative data required for an order. The second tier is the customer order line. This table contains the quantity of the items ordered and their price along with other supporting data. The third tier is the customer order release. This tier contains the quantities and delivery dates of their associated customer order line.

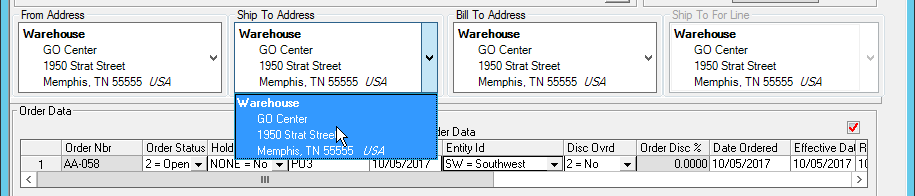

OMS+PLUS/OE provides expansive customer address support. There are three types of addresses associated with each order. Each type can contain multiple addresses. First, the order-from address indicates the buying entity or where the order originated. Second, the bill-to address indicates where the invoice should be sent. Third, the ship-to address indicates where the goods should be sent for this order. The ship-to address on the order is the default value for the line. Each line, however, may have a different ship-to address than the order. The ship-to address on the line may be changed or overridden by release. The ship-to address for the order, for example, may be Boston, while the line ship-to address is Pittsburgh and the release ship-to address is Chicago.

There are three ways to maintain customer order data. First, customer orders may be maintained via the Sales Order Window. This approach is always used to add customer order headers, lines and releases. Second, sales order releases may be maintained by customer. This window shows all the outstanding releases for a given customer. This maintenance is very helpful if the customer is asking for a pull-in or push-out of all of their outstanding releases. Third, customer order release data may be maintained by Catalog Item. This approach is very helpful if there are delivery problems with an item that is sold to many customers.

Four status options are available for orders, lines, and releases. First, the planned status indicates that an order is in process but nothing is firm. If the order is planned then all lines and releases are planned. Second, the open status indicates that an order is in process. The order must be in open status before any line may be in open status. A release cannot be in open status unless the line is in open status. Third, if an order is closed, then no further activity is expected. Orders may be changed from closed to open. An order may not be closed if any lines are in the open status. A line may not be closed if any of the associated releases are in an open status. Fourth, the cancelled status indicates that all work is to cease. If the order is cancelled, then all associated lines and releases are cancelled. If a line is cancelled, then all associated releases are also cancelled.

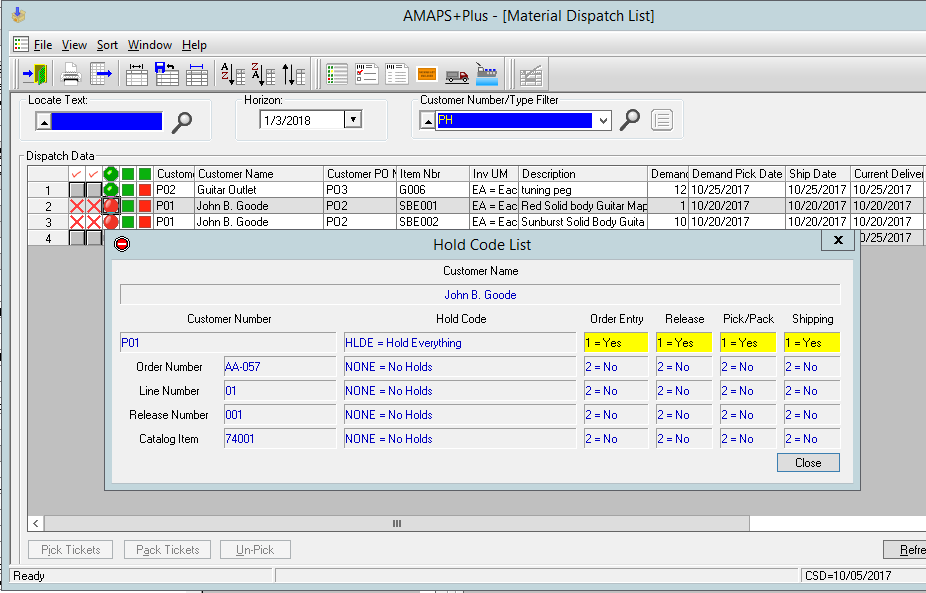

Hold codes are used throughout by OMS+PLUS/OS and OMS+PLUS/PPS. These hold codes may be specified by customer, order, line, or release. The hold codes are user specified. A given hold code may prohibit any or all of the following activities: shipping, order entry, and order release. If the hold code prohibits shipping, then OMS+PLUS/PPS will not allow the shipment to leave the factory. If the hold code prohibits order entry, then no new customer orders may be entered for that customer. If the hold code prohibits order release, then no additional production may be requested from the factory.

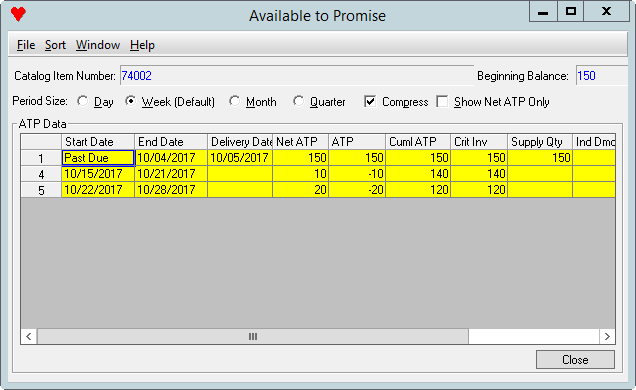

The Available-To-Promise query identifies the amount of an item that you can ship in the future by time period. The time period may be a day, week, month, or quarter and may be changed while viewing the ATP query. The query displays the ATP that is the planned deliveries less the expected customer orders by time period. The query next displays the cumulative ATP that is the sum of the prior ATP quantities up to that date. If the cumulative ATP is negative, then there is not enough product scheduled to support the customer's orders. The net ATP is the quantity available by time period after considering all the cumulative effect of both customer orders and planned deliveries. If, for example, the Cumulative ATP is negative, then the net ATP for all prior periods is zero.

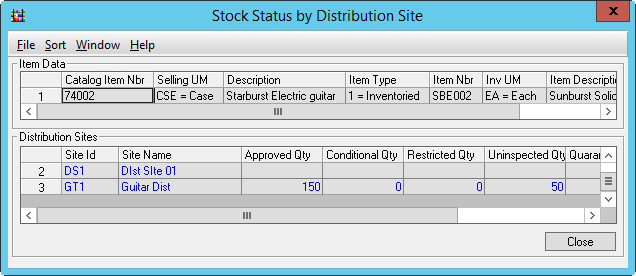

A Stock Status query is one click away. This query shows the location of inventory and whether it may be used to satisfy customer orders.